-

Who are the top 10 busway manufacturers in the industry?

Based on market influence, quality, and production capacity, leading busway manufacturers include both international giants and prominent Chinese companies. The top 10 typically include Schneider Electric, Siemens, ABB, Eaton, Cylon Elec...

-

Does Cylon Group operate a physical factory?

Yes, we have established a large-scale intelligent manufacturing base covering more than 30,000 square meters in Chuzhou City, Anhui Province. With a network of branches and offices in multiple cities, we are fully capable of conducting ...

-

What are the specifications and models of busways?

Busway systems are primarily categorized into four core types based on their construction and application. Their key specifications revolve around the pole configuration (4P/5P) and current rating classification.

-

What are the materials used in Cylon busway systems?

Cylon busways are constructed using three core component materials: high-conductivity T2 copper or aluminum conductors, specialized insulation layers like epoxy resin, and protective aluminum or steel casings. This combination ensures op...

-

What are the copper bar standards for Cylon sandwich (intensive) busway systems?

Cylon copper bars strictly adhere to GB/T 7251.2-2013 and JB/T 9662-2011 standards, utilizing high-purity T2 electrolytic copper. The system ensures high efficiency with a conductivity of ≥98.6% and a temperature rise limit strictly cont...

-

What are the standard specifications and dimensions for your company’s busway systems?

Busway dimensions are primarily determined by the insulation type and current rating, ranging from compact 100×50 mm units to heavy-duty 300×200 mm systems. All models are available in 4-pole (4P) or 5-pole (5P) configurations with a wid...

-

What are the common specifications, models, and price ranges for busway (busbar trunking systems)?

Busway systems typically range from 400A to 6300A in capacity and are available in sandwich, air-insulated, or cast resin types. Prices vary significantly based on the conductor material (copper vs. aluminum) and protection ratings, gene...

-

Does the track busway require regular maintenance?

Yes, while track busways are designed for high reliability and low upkeep, they do require periodic inspections to ensure electrical integrity and mechanical security. Regular check-ups focus on preventing thermal issues at connection po...

-

How to ensure a flawless mechanical connection for multi-section busway systems?

Achieving a flawless mechanical connection in multi-section busways requires meticulous attention to the alignment of conductor ends and the precise application of torque to joint bolts. By ensuring that every joint pack is seated correc...

-

How can I minimize the space required for busway routing in a narrow electrical shaft?

To minimize the footprint of a busway system, designers should prioritize the use of high-density sandwich-insulated bus ducts and leverage customized compact fittings such as offset elbows and specialized tap-off units. These strategic ...

-

Current Language

-

Change Language

-

Vertical Supports for Busway Systems

-

Horizontal Hangers for Busway Support Function

-

High-Reliability Overlapping Copper Busbars

-

Copper Flexible Busbar Soft Connectors for Busway

-

Safe Connectors/Jointers for Busway Units

-

Plug-in box: Robust Protection for Busway System Origins

-

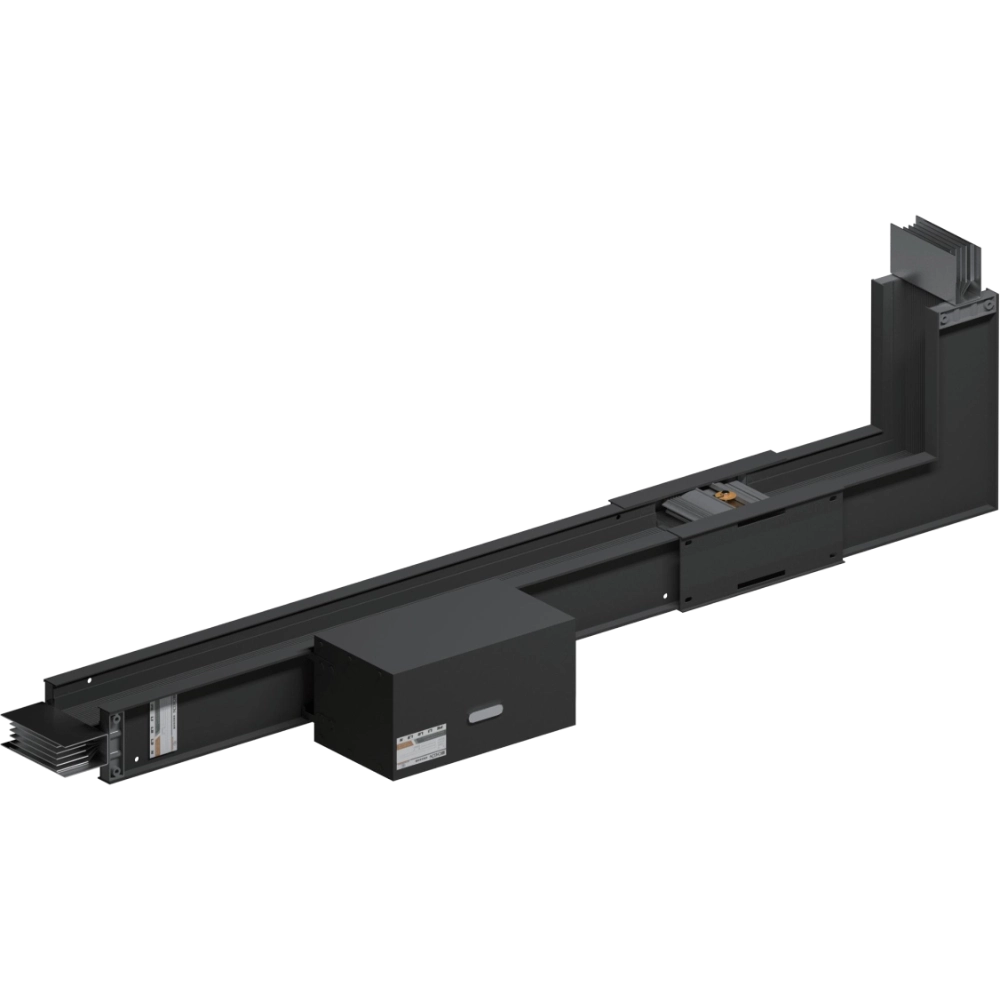

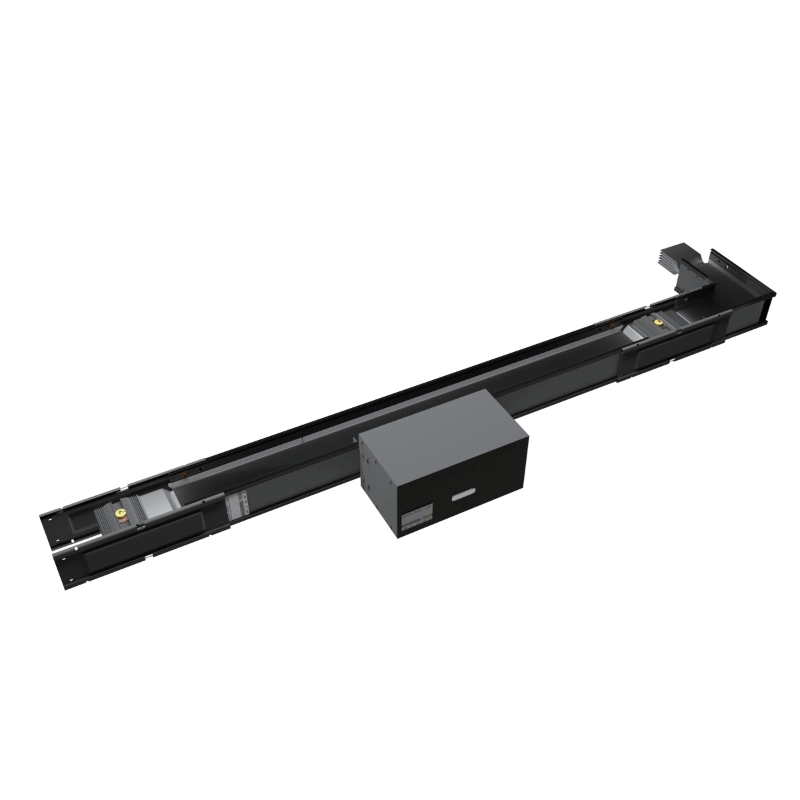

Feeder Box | Start-End Box: Robust Protection for Busway System Origins