Yes, while track busways are designed for high reliability and low upkeep, they do require periodic inspections to ensure electrical integrity and mechanical security. Regular check-ups focus on preventing thermal issues at connection points and maintaining a dust-free environment for the sliding or plug-in components.

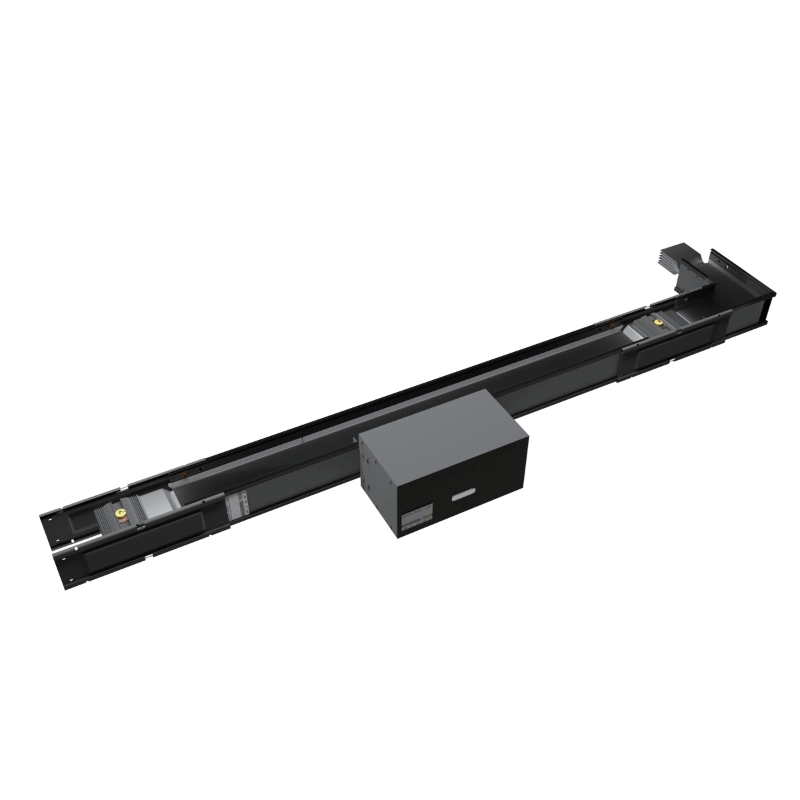

The common industry perception is that track busways (often used in data centers and high-tech labs) are “maintenance-free.” While it is true that they lack the complex moving parts of traditional switchgear, a “set it and forget it” mentality can be risky. The primary goal of maintenance here is not repair but prevention. Over time, even the most robust systems can be affected by thermal cycling—the expansion and contraction of conductors as power loads fluctuate—which may lead to the slight loosening of joint bolts or plug-in units.

A professional maintenance routine typically centers on thermal imaging (infrared scanning). This non-invasive technique is crucial for identifying “hot spots” at the joints or where the plug-in units meet the rail. If a connection shows an abnormal temperature rise, it’s a clear signal that the mechanical pressure has dropped or oxidation has occurred. Beyond thermal checks, physical cleanliness is vital. In many industrial or data center environments, the accumulation of conductive dust can bridge the gap between busbars, potentially leading to tracking or flashovers.

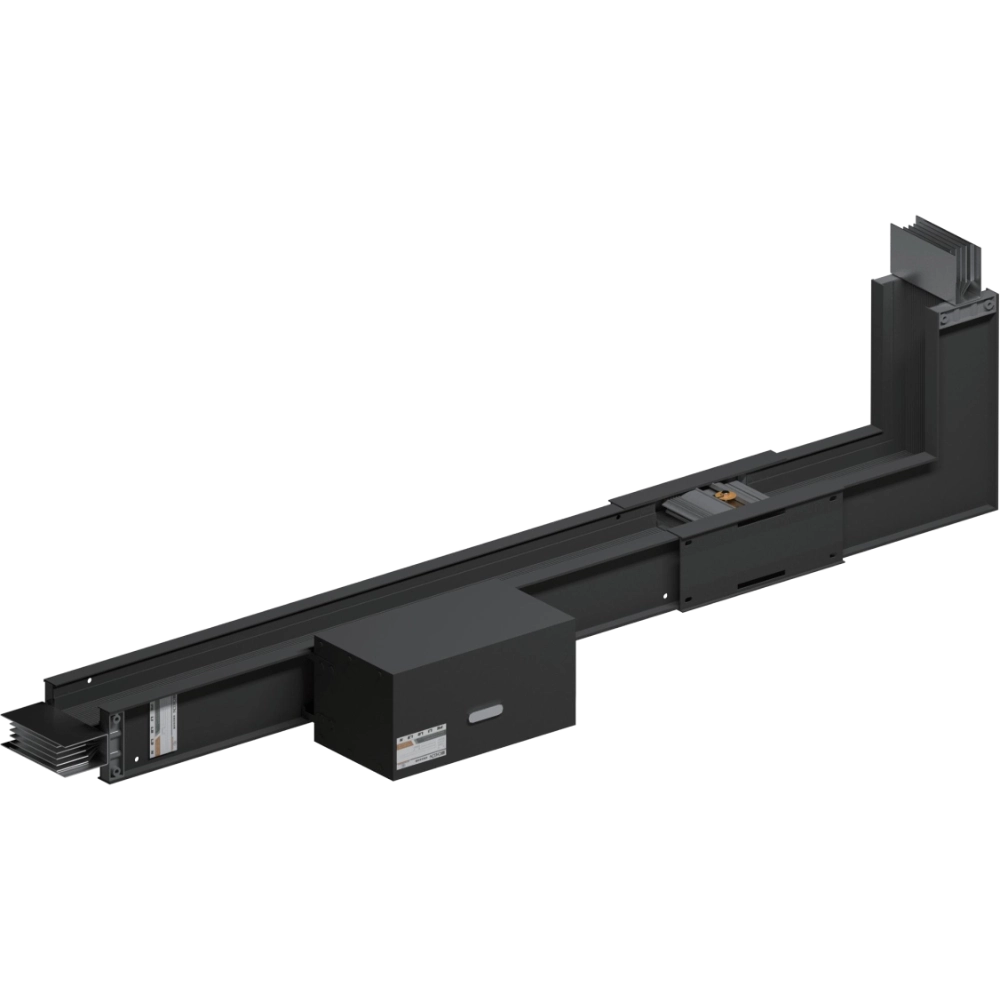

Furthermore, the “track” nature of the system means that plug-in units are often moved or added. Part of a solid O&M (Operations & Maintenance) strategy involves verifying that these units are seated correctly and that the grounding path remains continuous. Unlike traditional cabling, which is buried in trays, the busway is an exposed, rigid infrastructure. Therefore, a quick visual inspection for structural alignment and a check of the spring hangers to ensure they are still properly supporting the weight of the run can prevent long-term mechanical stress. In short, while the labor involved is minimal compared to cable systems, a consistent inspection schedule is what keeps a facility’s power backbone resilient.