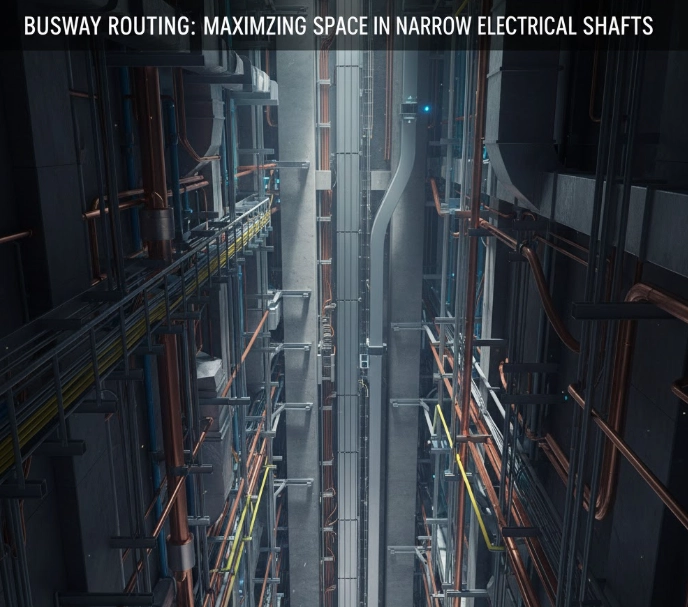

To minimize the footprint of a busway system, designers should prioritize the use of high-density sandwich-insulated bus ducts and leverage customized compact fittings such as offset elbows and specialized tap-off units. These strategic choices allow for tighter clearances and vertical alignment that significantly reduce the total volume occupied within a constrained electrical shaft.

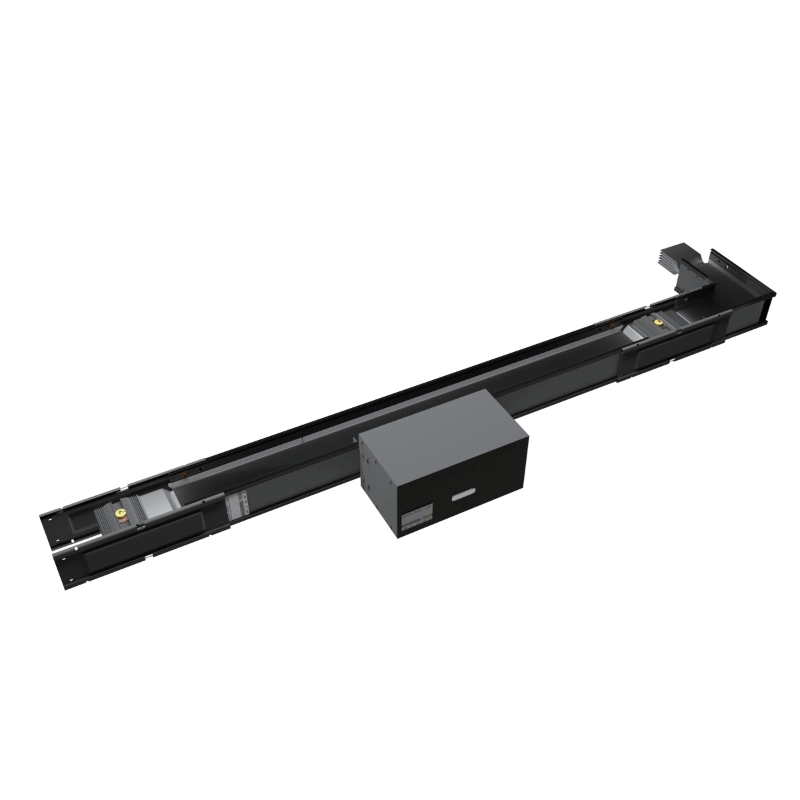

Navigating the spatial constraints of a modern high-rise requires a shift from traditional cabling to sophisticated busway systems. The most effective way to save space is by selecting a sandwich-type design (like the CY-L series) over air-insulated alternatives. Because the conductors are tightly packed without large air gaps, the overall dimensions of the ducting are drastically reduced. In a narrow shaft, every centimeter counts, and the sandwich construction offers the highest current-carrying capacity per square meter of cross-sectional area.

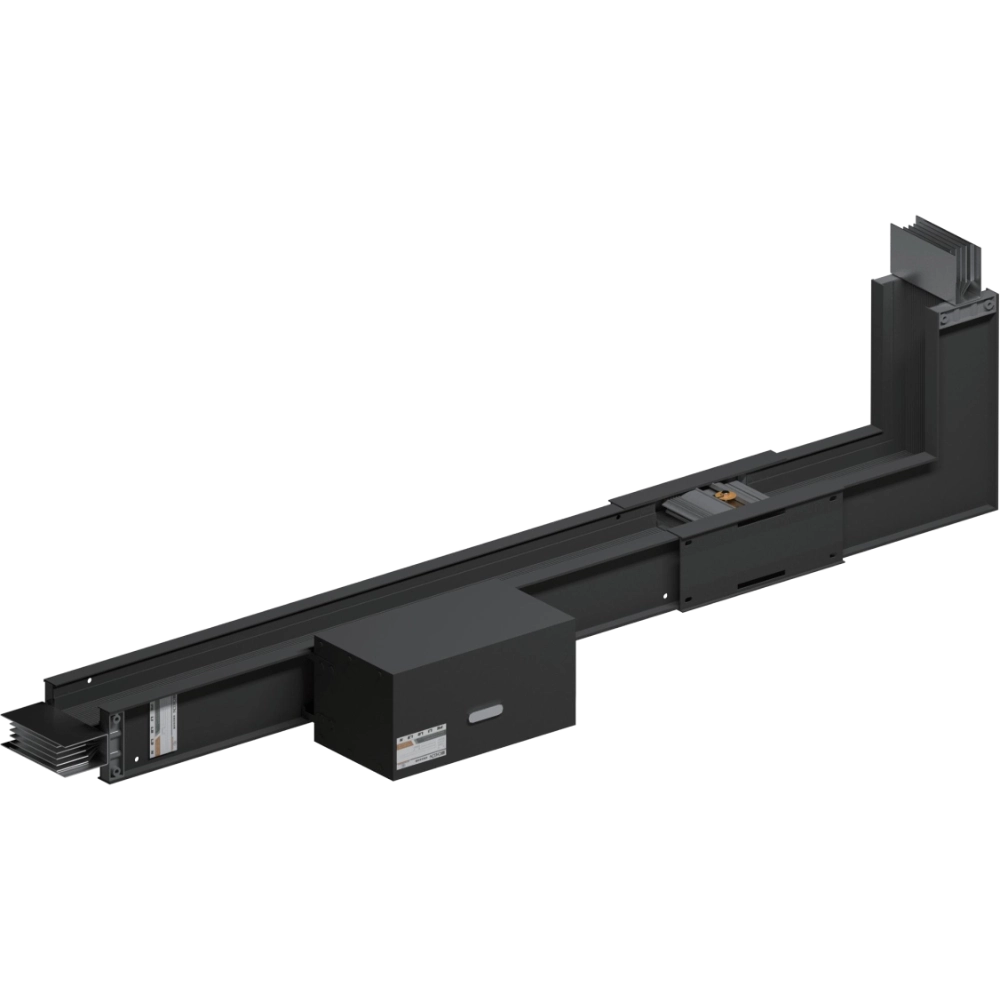

Beyond the straight lengths, the “geometry of the path” is where space is truly won or lost. Instead of standard, bulky elbows, designers should specify compact or customized fittings. For instance, using a “flatwise” offset allows the busway to hug the wall or structural beams more closely, bypassing obstructions that would otherwise force the entire run into the center of the shaft. Furthermore, the placement of tap-off units (plug-in boxes) should be staggered or vertically aligned with the narrowest profile of the busway to ensure they don’t protrude into required maintenance walkways.

Another critical design factor is the minimum clearance requirement. While safety codes dictate certain distances from walls for heat dissipation and installation access, a well-engineered busway with high thermal efficiency can often safely operate with a smaller footprint than a sprawling bundle of cables. By utilizing integrated spring hangers and support brackets designed for narrow profiles, you can consolidate the entire power distribution backbone into a single, vertical column that leaves ample room for other mechanical, electrical, and plumbing (MEP) services.