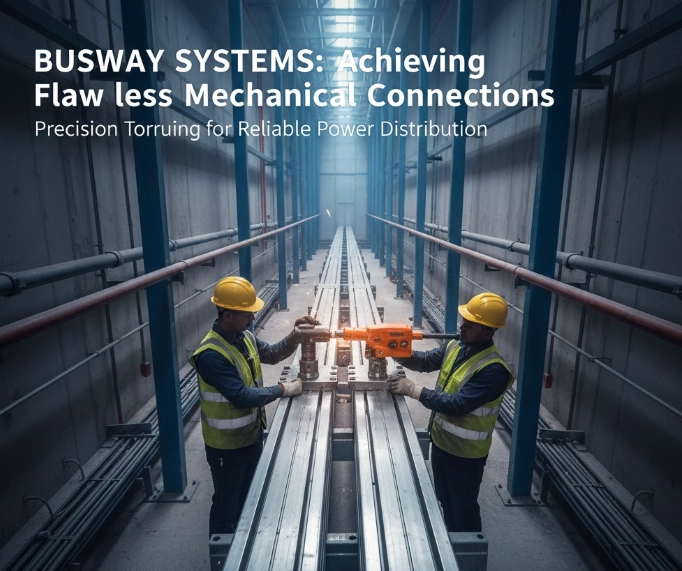

Achieving a flawless mechanical connection in multi-section busways requires meticulous attention to the alignment of conductor ends and the precise application of torque to joint bolts. By ensuring that every joint pack is seated correctly and tightened to manufacturer specifications, installers can prevent high resistance and potential thermal failure during operation.

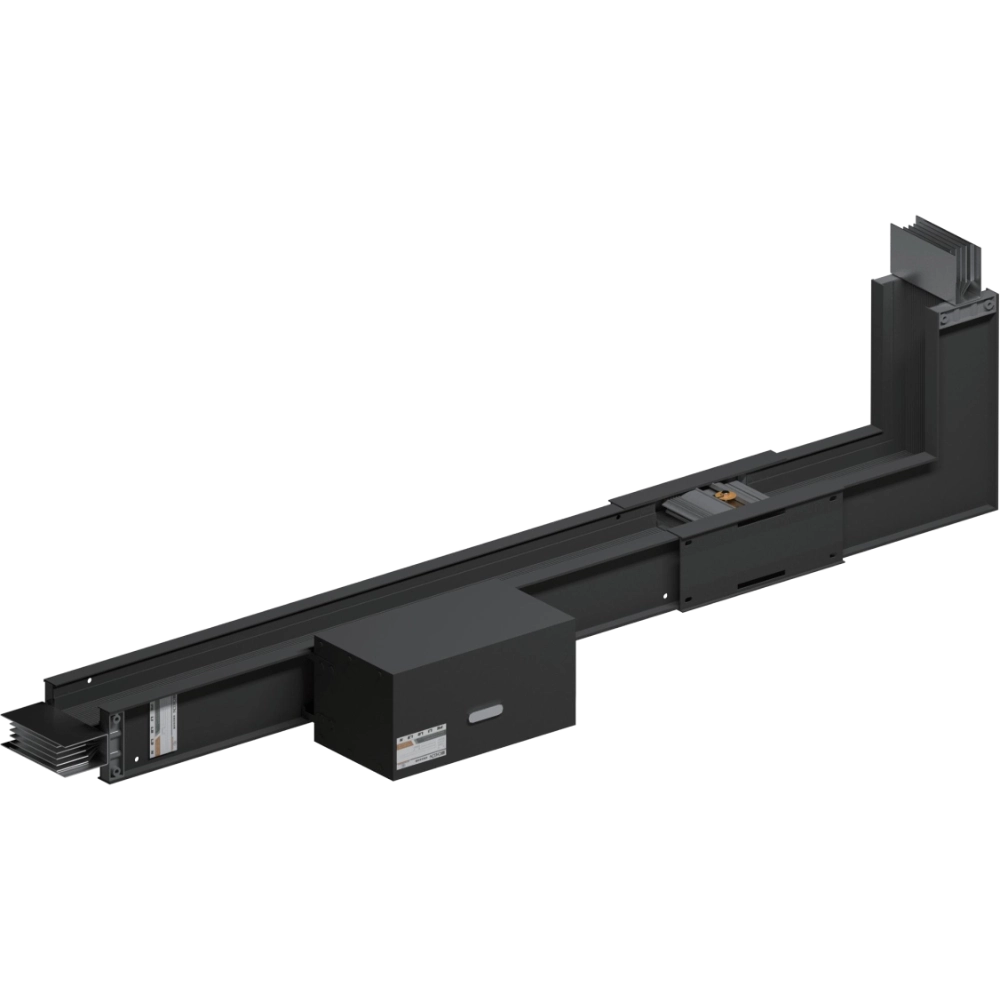

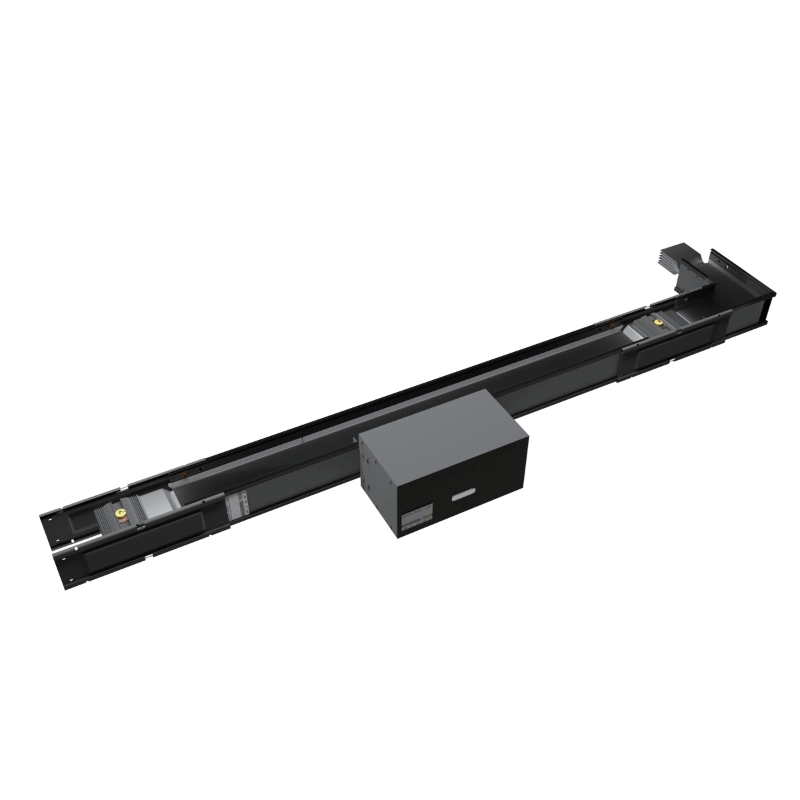

The integrity of a busway system is only as strong as its weakest joint. Unlike flexible cabling, a busway is a rigid assembly where multiple sections must be spliced together to form a continuous electrical backbone. The first step toward a perfect connection is meticulous alignment. Even a slight deviation in the vertical or horizontal plane can put undue stress on the joint pack, leading to “gapping” between the silver-plated or tin-plated conductor ends. Before a single bolt is turned, installers must ensure that the sections meet squarely and that the housing is properly supported by hangers to prevent sagging.

The “heart” of the mechanical connection is the joint bolt assembly. Most modern systems, like the CY-L Sandwich Busway, utilize high-tensile, double-headed torque bolts. The genius of this design lies in its simplicity: the outer head is engineered to shear off once the optimal clamping pressure—often around 80 Nm to 100 Nm—is reached. This provides a visual confirmation that the connection is neither loose (which causes arcing) nor over-tightened (which deforms the conductors). It is a best practice to use a calibrated torque wrench for a secondary check, especially in high-vibration environments like industrial plants or metro tunnels.

Finally, cleanliness cannot be overlooked. Any dust, debris, or moisture trapped within the bus duct joint during construction acts as a contaminant that increases contact resistance. Wiping down the contact surfaces with an approved cleaning agent and applying a thin layer of joint compound (if specified) ensures maximum conductivity. By combining structural alignment, precision torquing, and environmental cleanliness, Cylon can guarantee a system that is not just mechanically sound but electrically “invisible” in its efficiency.