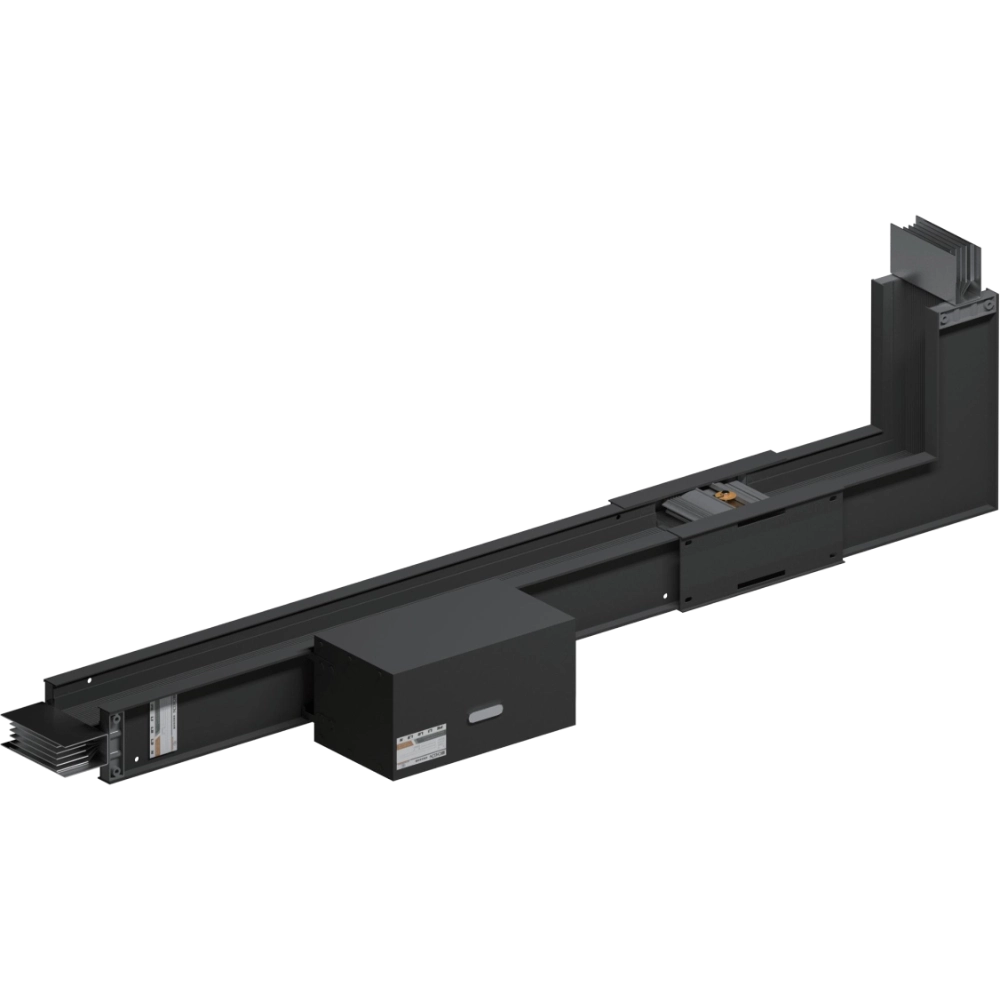

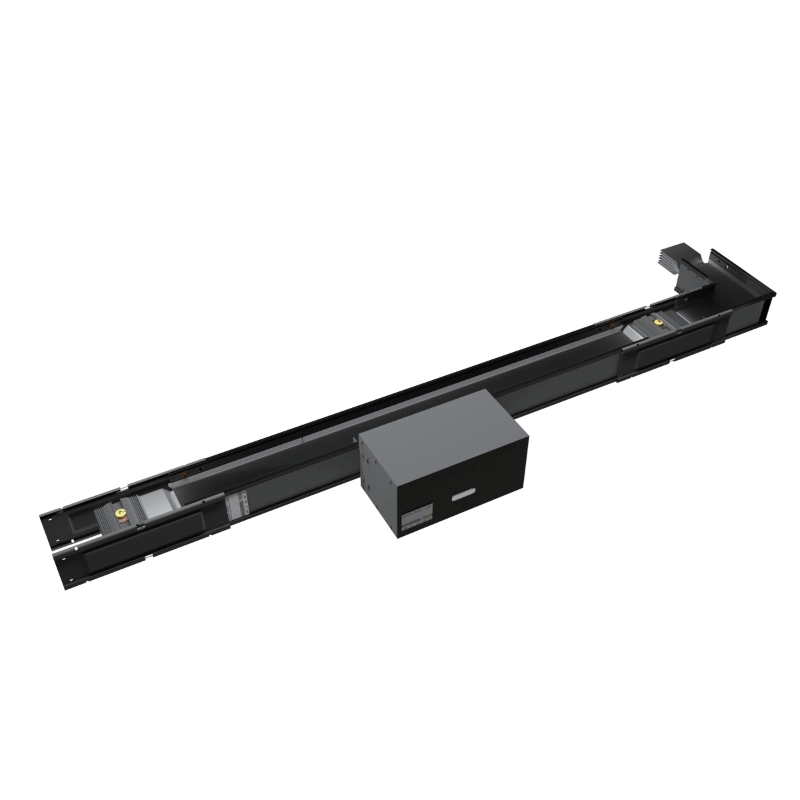

Vertical supports are essential components in busway systems during vertical installation, acting as the “spine” of the structure to ensure safe and stable routing through floors or shafts. By evenly transferring the busway’s weight to the building structure, they prevent issues such as connector loosening, deformation, or accidental falling caused by concentrated gravity.

With a robust design and scientifically defined installation spacing, vertical supports provide reliable mechanical reinforcement while enhancing electrical safety and long-term operational stability. Certain models feature adjustable structures, allowing installers to precisely correct alignment and maintain the busway’s vertical positioning.

Whether in high-rise buildings, industrial facilities, or data centers, vertical supports are indispensable for securing safe and stable vertical busway installations.

Vertical Supports for Busway Systems

Product Support :

PRODUCT FEATURES

-

Robust Structure & Premium Materials

Manufactured with high-quality carbon steel, stainless steel, or aluminum alloy, Cylon vertical supports are engineered to withstand different installation environments. Each material option offers distinct advantages—carbon steel for strength, stainless steel for superior corrosion resistance, and aluminum alloy for lightweight yet durable applications. With surface treatments such as galvanization, powder coating, or fire-retardant coating, the supports deliver long-lasting protection against rust, wear, and fire hazards.

-

Optimized Structural Design

The supports are designed with precision, offering options such as one-piece molding, reinforced ribs for added strength, and quick-locking mechanisms that improve stability and ease of assembly. This thoughtful engineering not only enhances load-bearing capacity but also ensures the busway system remains aligned and secure, even in demanding vertical installations across multiple floors.

26

Industry Experience

-

Easy Installation & Compatibility

Installation is made efficient with pre-drilled standard mounting holes that reduce the need for on-site modification. Adjustable height and angle options allow the supports to adapt to complex building layouts and construction challenges. They are also designed with compatibility in mind, capable of accommodating various busway specifications and models, ensuring flexibility across different projects.

-

Safety, Compliance & Environmental Adaptability

Each vertical support undergoes rigorous load-bearing, drop, and fatigue tests to verify long-term reliability. Certified to international and industry standards such as IEC, GB, UL, and CE, the supports meet strict safety and performance requirements. With proven fire-resistance levels and the ability to withstand harsh environments—whether humid, high-temperature, or corrosive—they guarantee safe operation throughout a lifecycle of 20 years or more. Suitable for high-rise buildings, hospitals, data centers, and industrial facilities, Cylon vertical supports deliver dependable performance in the most challenging conditions.

Why Choose Cylon Busway

-

Durable Insulation for Safety

Terminals are reinforced with robust insulation materials, ensuring safe and dependable operation. Halogen-free and eco-friendly, these materials offer long-term protection in demanding electrical environments.

-

Fully Sealed for Maximum Protection

The fully enclosed, tightly sealed structure prevents dust, moisture, and contaminants from entering. Compared to conventional jointed designs, it delivers superior reliability and extends the service life of your system.

-

Flexible and Easy to Maintain

Bolt-on connections and modular design make installation, inspection, and future system expansions simple and efficient, reducing downtime and operational risk.