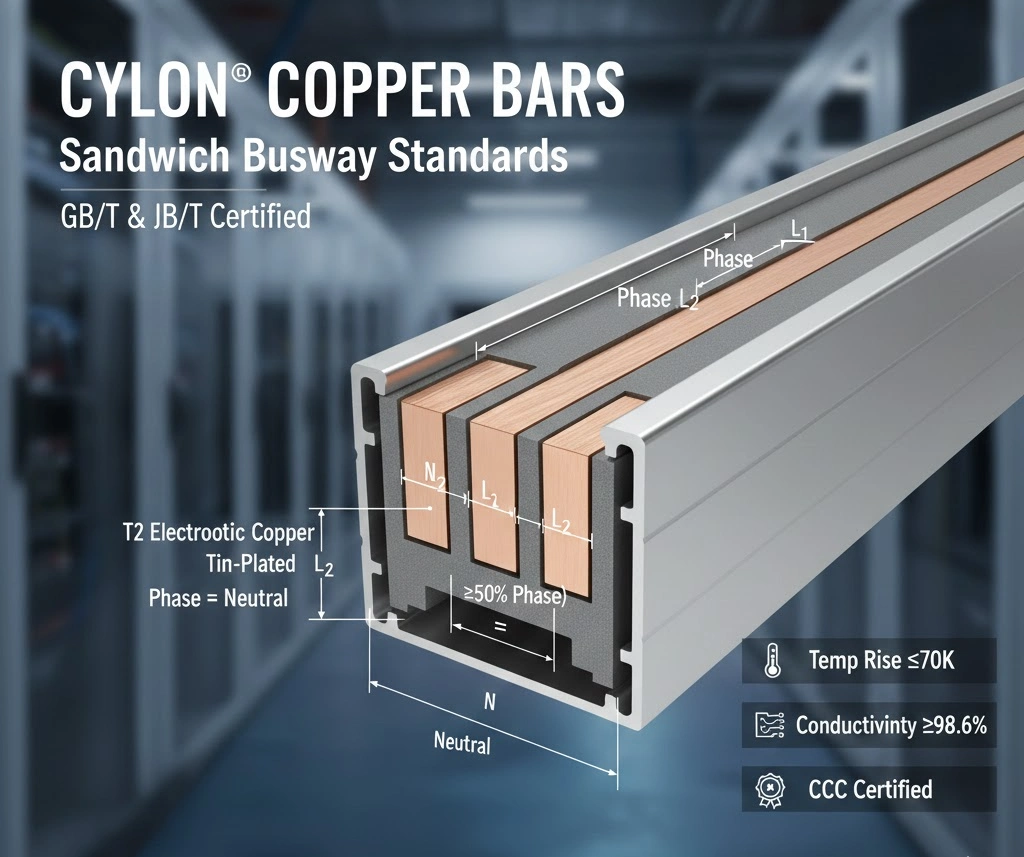

Cylon copper bars strictly adhere to GB/T 7251.2-2013 and JB/T 9662-2011 standards, utilizing high-purity T2 electrolytic copper. The system ensures high efficiency with a conductivity of ≥98.6% and a temperature rise limit strictly controlled under 70K.

1. Material Quality and Purity The heart of the busway system is the conductor quality. We use premium T2 electrolytic copper to ensure minimal power loss and maximum safety.

- Purity: Copper content is verified at ≥99.9%.

- Conductivity: Electrical conductivity reaches ≥98.6% IACS (International Annealed Copper Standard).

2. Geometric Specifications & Configuration Consistency in cross-sectional area is vital for balanced electrical loads and grounding safety.

- Phase & Neutral: The cross-sectional area of the Neutral (N) bar is identical to the Phase bars (100% capacity).

- Earth (PE): The cross-sectional area of the Protective Earth (PE) bar is at least 50% or more of the Phase bar’s cross-section to ensure safe fault current discharge.

3. Manufacturing & Surface Treatment The durability of the connection depends on the surface integrity of the conductor.

- Tin Plating: The entire length of the copper bar is tin-plated to prevent oxidation and reduce contact resistance.

- Surface Integrity: Bars must be free of scratches, burrs, or sharp edges. Any process that compromises the structural integrity of the conductor is strictly prohibited.

4. Performance & Safety Certification Every system must pass rigorous testing to ensure long-term operational stability.

- Temperature Rise: Must remain ≤70K under full load conditions to prevent insulation aging.

- Current Density: Design current density is maintained at ≤2A/mm² to optimize heat management.

- Certification: All products are CCC (3C) certified and must pass mandatory temperature rise and insulation type tests.