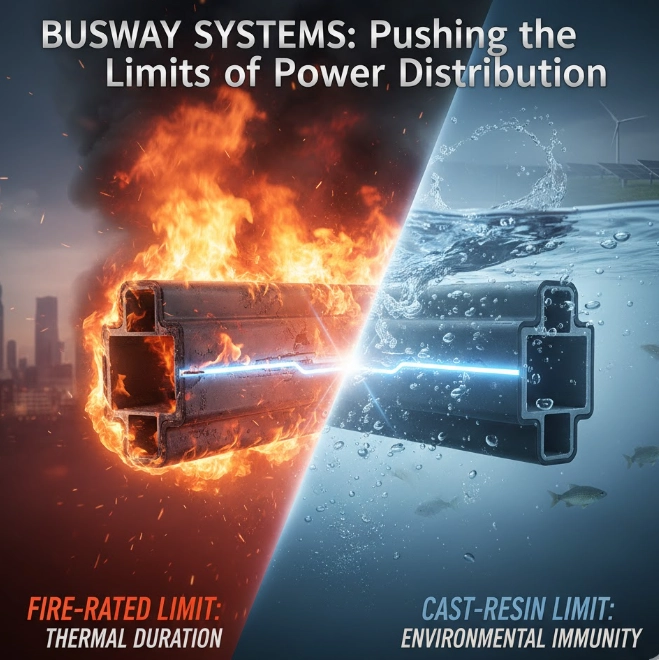

Fire-rated busway is engineered to maintain electrical integrity during active fires, prioritizing life safety, whereas cast-resin busway is built for total environmental immunity, focusing on waterproof and chemical-resistant durability. While both offer extreme protection, one saves the building during a crisis, while the other survives the harshest daily conditions.

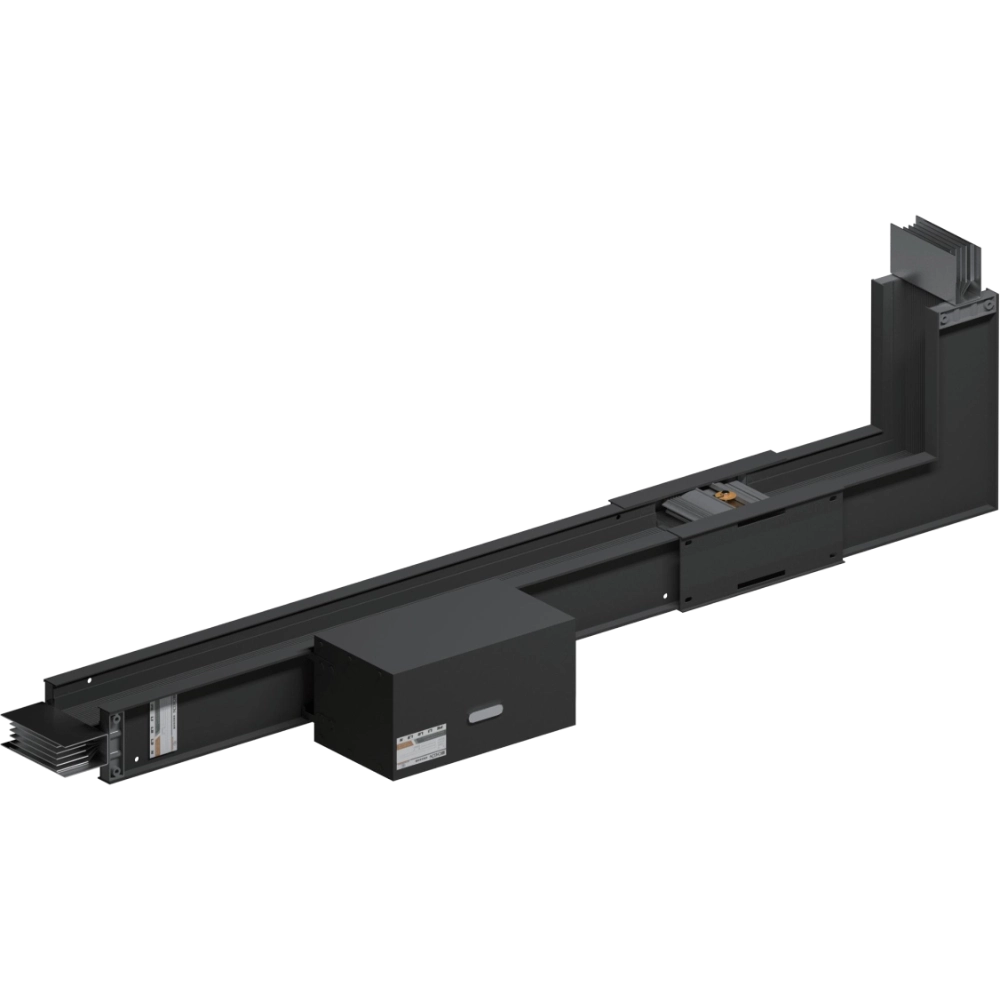

When comparing the performance limits of these two systems, it is essential to distinguish between endurance and resilience. A fire-rated busway is a “hero” component. Its primary performance limit is defined by time and temperature—typically tested to withstand $950°C$ to $1050°C$ for up to 3 hours (E-180/B-180 ratings). Its boundary is reached when the internal insulation finally degrades under sustained thermal stress. Its mission is specific: keep the fire pumps and emergency lifts running long enough for evacuation. Once the fire is extinguished, the system has usually reached its “limit” and requires replacement.

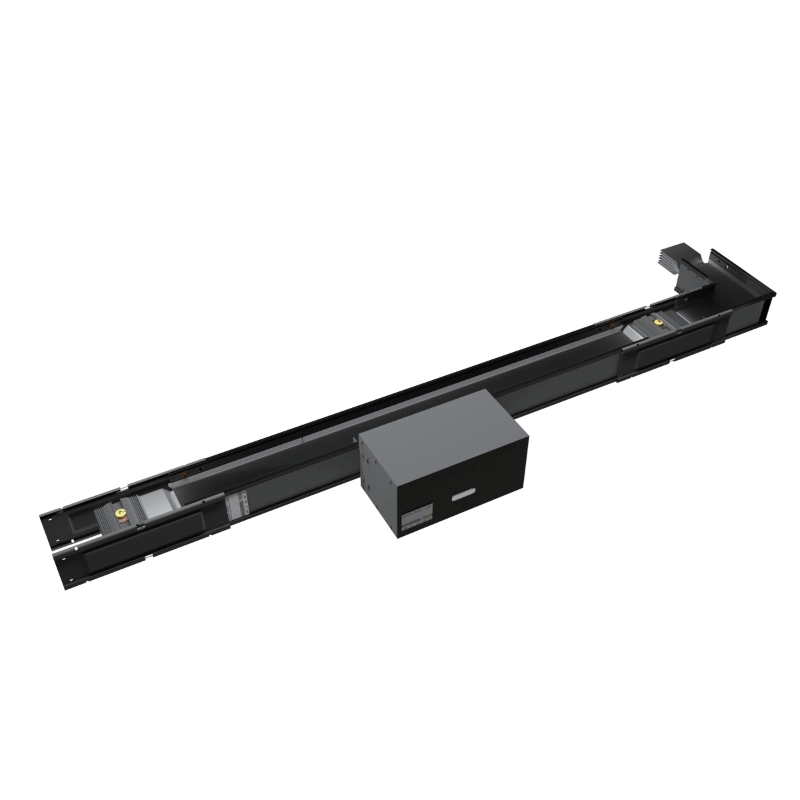

On the other hand, Cast-Resin Busway (often called Epoxy or Resin-Encapsulated) is an “immortal” component designed for longevity in brutal environments. Its performance limit is defined by its Ingress Protection (IP) and mechanical strength. With a rating of IP68, its limit for water submersion is virtually nonexistent for standard flooding scenarios, and its IK10 impact rating makes it nearly impervious to physical damage. Unlike fire-rated systems, cast resin is often “non-ventilated,” meaning its thermal limit is tied to its heat dissipation efficiency. It excels in chemical plants, outdoor tropical zones, or offshore platforms where salt spray and humidity would destroy standard ducting.

In short, the limit of a fire-rated system is thermal duration, while the limit of a cast-resin system is its continuous current-carrying capacity within its solid, airtight enclosure.